Virtual NVH Analysis: The Key to a Quiet and Comfortable Vehicle

Today, when customers expect not only performance and safety but also maximum driving comfort, the NVH analysis (NVH – Noise, Vibration, Harshness) plays a crucial role in the design of modern vehicles. With advanced simulation tools, we can now accurately predict where noise originates, how it propagates, how it affects the occupants, and what design modifications can suppress it – all before a single prototype is built.

What is NVH Analysis and Why is it Important?

NVH analysis helps understand and reduce the transmission of noise and vibrations within the vehicle. It focuses on noise and vibration sources, noise propagation paths, and how the noise is perceived by passengers, considering:

- Noise originated in car body – such as rolling noise transmitted through the chassis or noise coming from the engine

- Aerodynamic noise – transmitted through the body

- Interior acoustics – cabin resonances and the effect of fillings, reinforcements, and trims

- Vibrational comfort – vibrations negatively affect the driving experience and increase occupant fatigue

The goal is to achieve the desired level of acoustic and vibrational comfort for occupants while meeting all exterior noise regulations.

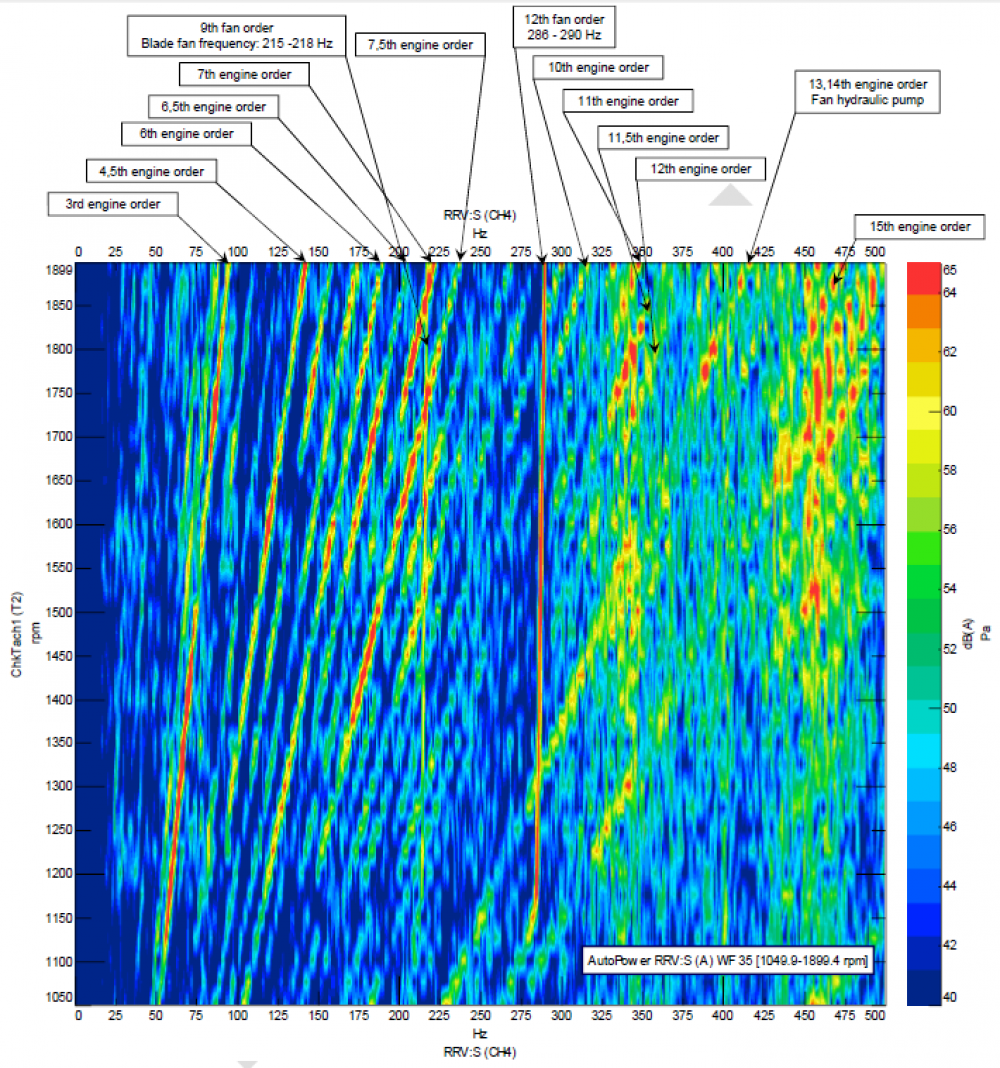

(The waterfall diagram shows the complexity of engine noise at different RPMs.)

How Does NVH Simulation Work?

To cover the full audible frequency spectrum (0–20,000 Hz), we use a combination of several computational methods:

Finite Element Analysis (FEA)

Used mainly for low-frequency phenomena (up to ~500–1000 Hz), such as:

- Resonances of the body and components

- Vibration transmission from engine, suspension, and road

- Vibro-acoustic interactions (e.g., between structure and acoustic cavity)

Statistical Energy Analysis (SEA)

Used for higher frequencies (typically above 1–2 kHz), where:

- The wavelength is short

- Modelling detailed geometry becomes computationally too intensive SEA analyses energy transmission between panels, fillings, and acoustic compartments.

Boundary Element Method (BEM)

Ideal for simulating sound propagation in open space (e.g., vehicle exterior noise):

- Used to simulate acoustic field radiation to the surroundings

- Advantage: only the boundaries of the air volume are modelled, not the entire space

- Often used in ACTRAN in combination with FEA for hybrid vibro-acoustic analysis

Ray Tracing

Used for very high frequencies or large spaces (e.g., aircraft or train cabins):

- Simulates reflection and attenuation of acoustic rays on surfaces

- Tracks acoustic energy along direct paths from source to receiver

Modal and Vibro-Acoustic Reduction (Component Mode Synthesis, Craig-Bampton)

Enables simplification of large structure simulations while preserving key dynamic behaviour:

- Model reduction for reuse (e.g., platforms, subassemblies)

- Suitable for hybrid analyses or integration into system models

Hybrid FEA/BEM or FEA/SEA Approaches

Combinations of methods are frequently used in practice, such as:

- FEA for structure + BEM for acoustics (e.g., engine cover + surrounding space)

- FEA for low frequencies + SEA for high frequencies (e.g., cabin interior acoustics)

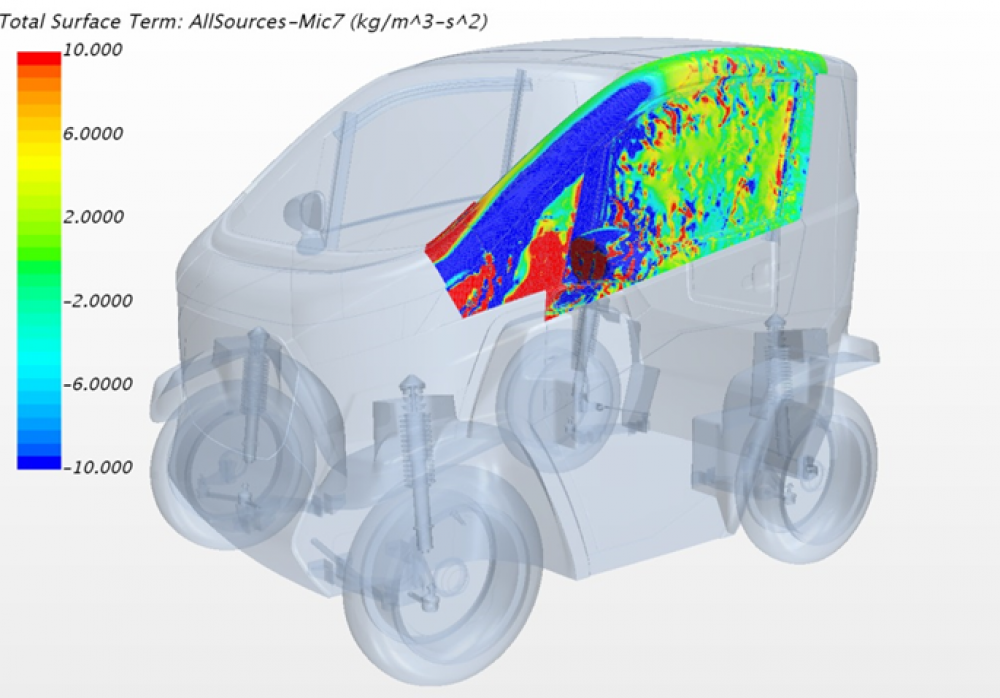

(Airborne noise projection in the window area)

Virtual Vehicle Model

A typical acoustic model can include over 50 million degrees of freedom. It combines:

- Structural mesh of the body and powertrain

- Interior acoustic cavity – the cabin space modelled as an acoustic field

- Panels, trims, and seals – with damping and transmission properties

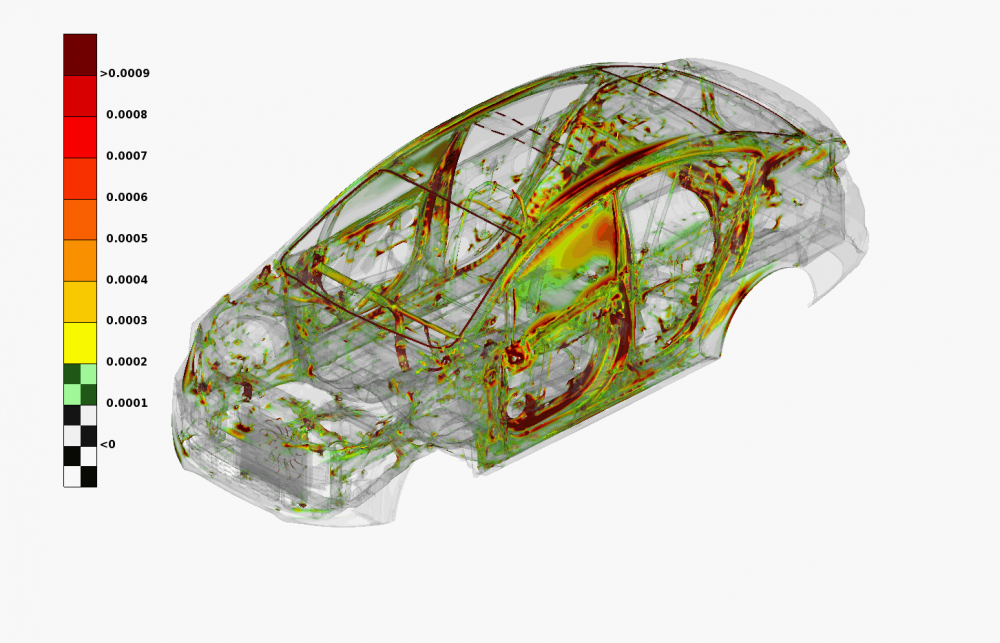

(Detailed description of structural stiffness is crucial to understanding acoustic response.)

Inputs and Outputs of the Simulation

Inputs:

- CAD model geometry

- Material properties (modulus of elasticity, damping, density, impedance characteristics)

- Excitation sources (e.g., engine forces, road inputs, airflow)

- Boundary conditions and loads

Outputs:

- Sound pressure levels in the cabin

- Vibration spectra at critical locations

- Noise transfer intensity maps

- Identification of dominant propagation paths

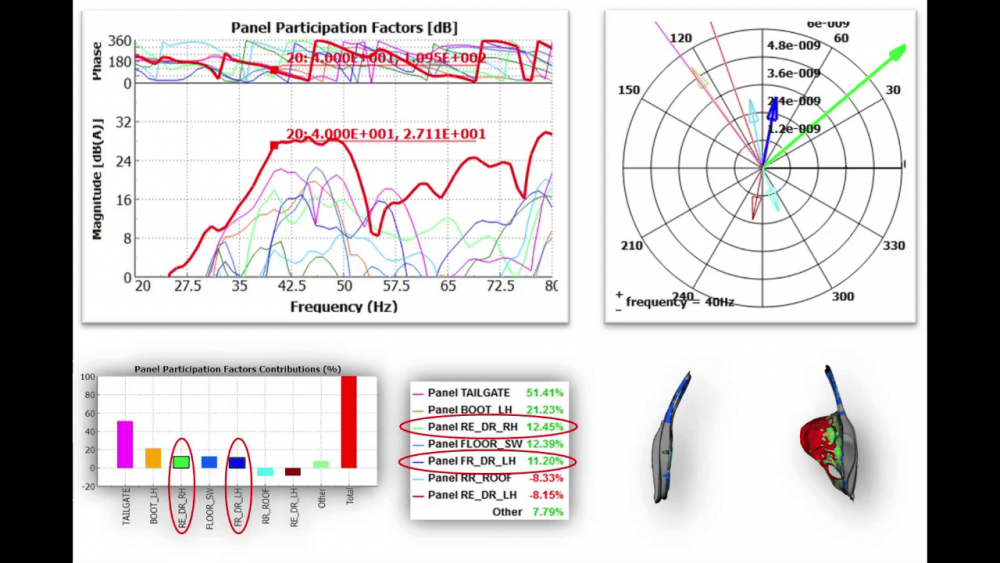

(Panel contribution analysis to the overall noise balance)

Experimental Validation

To ensure model reliability, we perform experimental validation using:

- Up to 110 accelerometers and microphones

- Strategic placement on the body and in the interior

- Comparison of simulation and measurement data (e.g., during road tests)

(A major strength of IDIADA is the ability to simulate and test under one roof)

Conclusion

NVH analysis is now an integral part of vehicle development. Thanks to digital twins, powerful simulation tools (e.g., ABAQUS, ACTRAN, NASTRAN), and integration with physical testing, we can optimize designs earlier, faster, and more cost-effectively. The result is a quiet, refined, and comfortable vehicle that meets both market and regulatory demands.

Want to learn more about NVH simulations?

Get in touch – we would be happy to show you how virtual acoustic analysis can benefit your project.